Automatic diecutter from sheets.

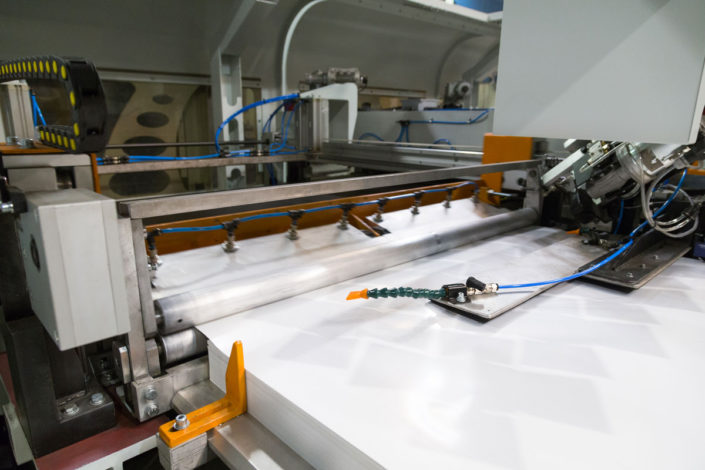

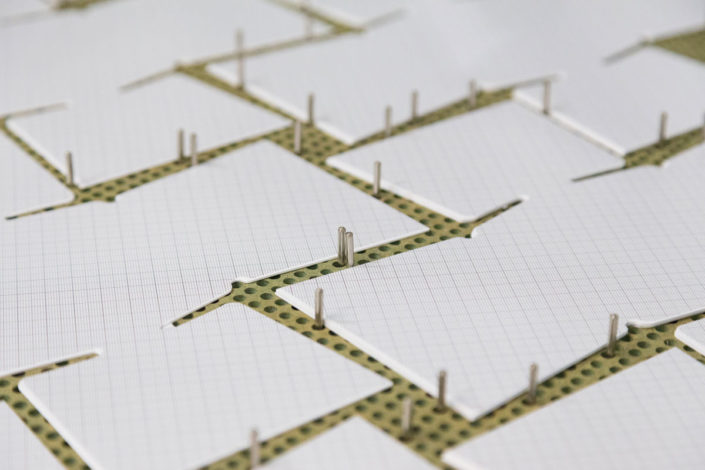

- Automatic collection of the labels, counted and separated from the paper waste.

- Starting time is 20 minutes, from the setting until the labels collection.

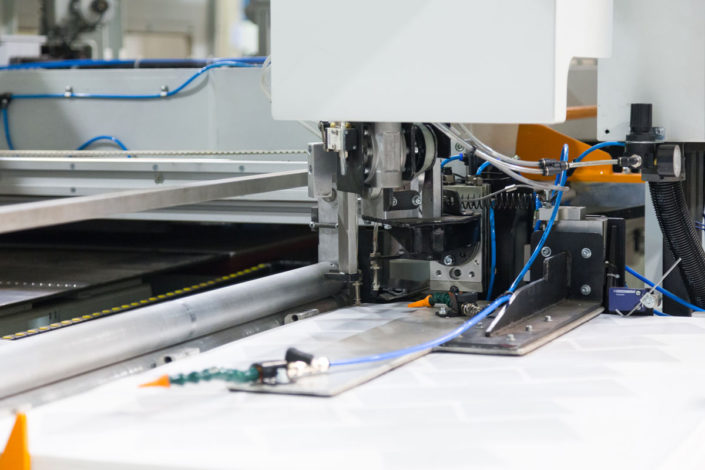

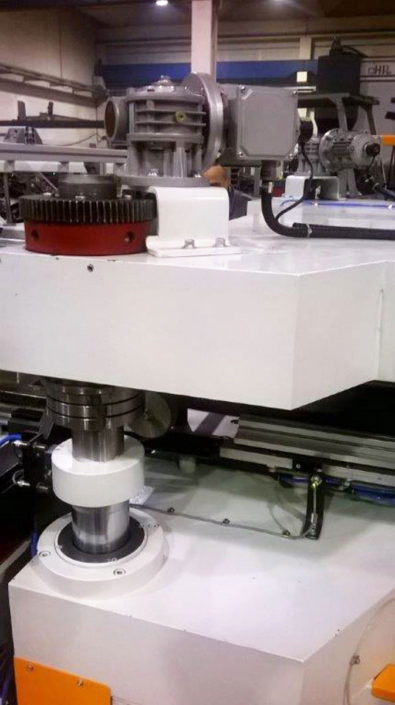

- Four electronically controlled axes.

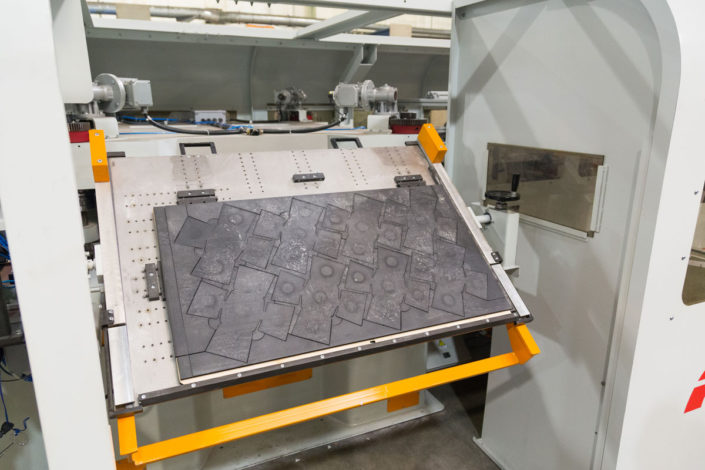

- Died used conventional steel-wooden “American”.

- Home brand ejecting devices, male/female.

- Only one operator for the whole line.

- Goods and services at the best price/quality ratio.

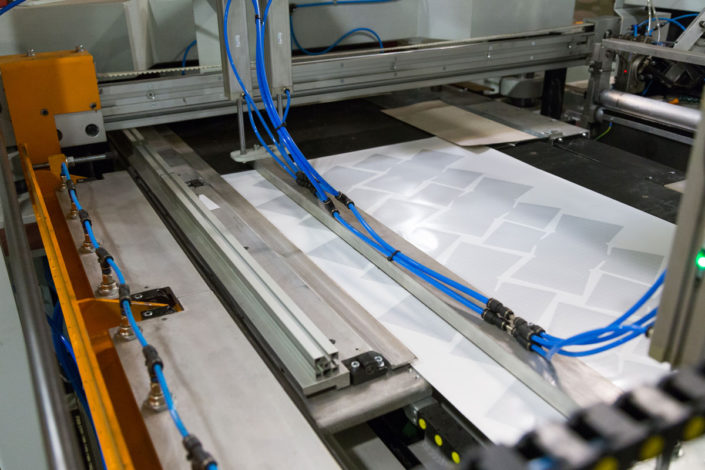

This machine, BF 1000- 10 F,is the result of decades of development in the flat bed die-cutting sector and, when related to other brands’ products, it offers many key market benefits. The machine allows you to cut many sheets at the same time (from 10 up to 30), its sheet production is minimum 5000 sheets per hour and maximum 14000 sheets per hour.

It is a full-hydraulic, four columns vertical press and its maximum cutting pressure is 180 Tons. It has four mechanical stops and they can be electronically controlled in order to set the machine cutting depth. The machine supports traditional steal made die-cutting devices/ wooden “american” devices.

This die-cutting machine is recommended for PPC, IML, such plastic materials, and paper cutting processes and automatic labels collecting processes. There’s also a four axes touch screen system, which allows you to get a sheet placement tolerance of 0,03mm.

Technical data:

| Model | Min. sheet size | Max. sheet size | Register precision | Gripper margin | Min. speed (sph) | Max. speed (sph) | Installed power | Net weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|

| BF 1000|10F – 180 ton | mm 600×900 | mm 760×1.060 | mm ± 0,03 | mm 15 | 5.000 | 14.000 | HP 20 | TON 15 | mt 8,3×3,0x2,0h |

| BF 700|10F – 140 ton | mm 400×600 | mm 560×760 | mm ± 0,03 | mm 15 | 5.000 | 14.000 | HP 18 | TON 11 | mt 7,0×2,2×2,0h |

| BF 500|10F – 120 ton | mm 300×400 | mm 460×560 | mm ± 0,03 | mm 15 | 5.000 | 14.000 | HP 15 | TON 8 | mt 5,5×1,8×2,0h |